To read this content please select one of the options below:

Please note you do not have access to teaching notes, an analysis of supply chain management research by topic.

Supply Chain Management

ISSN : 1359-8546

Article publication date: 30 April 2018

Issue publication date: 9 May 2018

This paper aims to review logistics and supply chain management topics where theories have been applied to better understand the supply chain management (SCM) discipline identity. The purpose is threefold: to identify research topics in logistics and supply chain management where one or more theories have been examined; provide commentary on the theories that have been applied to the various logistics and SCM research topics; and to provide reference material and direction for future research.

Design/methodology/approach

This structured literature review (SLR) examines research papers in logistics and SCM from 1991 to 2015 published in eight leading academic journals. Papers in the data set are grouped by topic and further analyzed in terms of research method, purpose, year and journal.

This research categorizes papers by the topics that were studied to understand important insights about how these topics have been examined by researchers. Within each topic area, theories that researchers have used to investigate the topics are identified. This method exposes insights such as: how topics have evolved over time, which topics have lost prominence, which topics may be particularly promising for future research and how topics are treated in the literature.

Originality/value

Despite multiple calls for clarification regarding how theory has been used in logistics and SCM, the logistics and SCM disciplines continue to grow without adequate research on how theory has been used to examine SCM topics. This SLR therefore provides a broad compilation of logistics and SCM research that uses named theories and that is organized by SCM topic to better understand the SCM discipline.

- Supply-chain management

Swanson, D. , Goel, L. , Francisco, K. and Stock, J. (2018), "An analysis of supply chain management research by topic", Supply Chain Management , Vol. 23 No. 2, pp. 100-116. https://doi.org/10.1108/SCM-05-2017-0166

Emerald Publishing Limited

Copyright © 2018, Emerald Publishing Limited

Related articles

All feedback is valuable.

Please share your general feedback

Report an issue or find answers to frequently asked questions

Contact Customer Support

Logistics Trends, Challenges, and Needs for Further Research and Innovation

- First Online: 01 January 2015

Cite this chapter

- Uwe Clausen 3 , 4 ,

- Joost De Bock 5 &

- Meng Lu 6

Part of the book series: Contributions to Management Science ((MANAGEMENT SC.))

3608 Accesses

4 Citations

Logistics and transport are central elements and pre-conditions of worldwide trade and business. Sustainable transport solutions are vital for societal acceptance: economic growth with less resources and even less environmental impact will be crucial for European countries and globally—access to markets at reasonable transport prices is a cornerstone for the benefits of globalisation. Sustainability in logistics includes ecological, economical and social objectives. Challenges arise from a global, competitive environment, restrictions, social or ecological concerns, as well as deficits in information flows, knowledge transfer or well integrated ICT applications. This chapter provides an overview of the trends and challenges in the area of logistics and supply chain management and addresses the needs for research and innovations. In addition, it describes the structure and the main themes of the other chapters of this book.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Similar content being viewed by others

Logistics Research and the Logistics World of 2050

Future Logistics: What to Expect, How to Adapt

Introduction and Overview

Clausen U, Hesse K (2012) Eco-efficient logistic processes. In: Information Technology Methoden und innovative Anwendungen der Informatik und Informationstechnik, February 2012, pp 24–32

Google Scholar

COM (2011) 144 Final. White paper: roadmap to a single European transport area—towards a competitive and resource efficient transport system. European Commission, Brussels, 28 March 2011

DHL (2012) Delivering tomorrow—logistics 2050, A scenario study. DHL, Bonn

Drewry (2011) Container market review and forecast. Drewry, London

ECTRI (2014) ECTRI (European Conference of Transport Research Institutes) Position on the second work programme (2016-2017), Brussels, July 2014

EffizienzCluster LogistikRuhr (2012) http://www.effizienzcluster.de

International Energy Agency (2014) Key world energy statistics. IEA, Paris

IPCC (2014) Climate change. Synthesis report. IPCC (Intergovernmental Panel on Climate Change), Geneva. http://www.ipcc.ch/pdf/assessment-report/ar5/syr/SYR_AR5_LONGERREPORT_Corr2_OnlinePDF.pdf

Meteo World (2014) CO2 crosses 400 ppm threshold throughout northern hemisphere. http://www.wmo.int/pages/publications/meteoworld/CO2Crosses.html

United Nations (2013) World population prospects: the 2012 revision. Population Division of the Department of Economic and Social Affairs of the United Nations Secretariat, June 2013. United Nations, New York, NY

WINN Consortium (2012) Logistics innovation for a more sustainable and competitive industry—Towards a European technology platform logistics (version 08). WINN (European Platform Driving KnoWledge to INNovations in Freight Logistics) Consortium, Brussels

World Bank (2007) Logistics performance index 2007. World Bank, Washington, DC

World Bank (2010) Logistics performance index 2010. World Bank, Washington, DC

World Bank (2012) Logistics performance index 2012. World Bank, Washington, DC

Download references

Author information

Authors and affiliations.

Fraunhofer Institute for Material Flow and Logistics IML, Joseph-von-Fraunhofer-Str. 2, 44227, Dortmund, Germany

Uwe Clausen

Institute Transport Logistics ITL, TU Dortmund, Joseph-von-Fraunhofer-Str. 2, 44227, Dortmund, Germany

European Commission, Brussels, Belgium

Joost De Bock

Dutch Institute for Advanced Logistics, Princenhagelaan 13, 4813, DA Breda, The Netherlands

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Uwe Clausen .

Editor information

Editors and affiliations.

Dutch Institute for Advanced Logistics, Breda, The Netherlands

Rights and permissions

Reprints and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Clausen, U., De Bock, J., Lu, M. (2016). Logistics Trends, Challenges, and Needs for Further Research and Innovation. In: Lu, M., De Bock, J. (eds) Sustainable Logistics and Supply Chains. Contributions to Management Science. Springer, Cham. https://doi.org/10.1007/978-3-319-17419-8_1

Download citation

DOI : https://doi.org/10.1007/978-3-319-17419-8_1

Published : 20 May 2015

Publisher Name : Springer, Cham

Print ISBN : 978-3-319-17418-1

Online ISBN : 978-3-319-17419-8

eBook Packages : Business and Management Business and Management (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Download Free PDF

LOGISTICS AND SUPPLY CHAIN MANAGEMENT - AN OVERVIEW

2018, Shanlax publication

A logistics and inventory network administration have risen as key business concerns. Be that as it may, despite the fact that familiarity with the significance of co ordinations and the inventory network is currently substantially more prominent, there are as yet numerous organizations where these thoughts still can't seem to be completely executed. The uplifting news however is that, by and large, logistics and store network administration have moved significantly higher up the plan in associations in each industry and area. This new release of Logistics and Supply Chain Management expands on the thoughts and ideas of the prior renditions yet as new reasoning develops and best practice shows signs of improvement, the requirement for correction and refreshing winds up unavoidable. For instance, in this third release there is a much more prominent accentuation on responsiveness, mirroring the expanded instability of interest in numerous business sectors. Another expansion is another section on production network chance, perceiving that as systems turn out to be more perplexing so does their weakness to disturbance increment.

Related papers

International Journal of Recent Technology and Engineering , 2019

Logistics Management is an effective system for the companies to deliver the products to the customers at the exact place where they demands at right time with right cost. Logistics management comprises the planning, implementation and control of the flow of raw materials and finished goods from the suppliers to the customers. This study is conducted to understand the conception of logistics and its significance. This study is to show the main functions of the logistics, aim, tactics and its various components. Nowadays most of the major companies are enforced to lessen their business expenditures because of the globalization and the companies are finding ways to reduce the costs without affecting the productivity. This made them to practice a new management tactics like Supply chain management and e-logistics. E-logistics provides the idea of logistics business into the modern world through the internet and completely changes the concept of simple logistics into e-logistics. E-logistics is the most modern technology in the field of logistics which brings the whole business world into a small online e-world. This novel set of communication with better computing and collective skills changes the new logistics into a customer oriented technology by data sharing, providing information and exact statistics with the supply chain customers. E-logistics helps in managing the new challenges in the supply chain field. The main components of the e-logistics are multi-channel operations, cross-border tasks, warehouse plan and inventory, planning, estimating and performance management. This study targets to understand the main benefits and the new tasks between logistics and e-logistics.

res publication, 2011

Role of Ontology in NLP Grammar Construction for Semantic based Search Implementation in Product Data Management Systems. Zeeshan Ahmed, Thomas Dandekar and Saman Majeed 1-40 2 Influence of Emotional Intelligence on Academic Self-Efficacy and Achievement. Armin Mahmoudi 41-52 3 Role of Online Education in Indian Rural Area. Prof. Bhavna Kabra, Prof. Swati Sood and Prof. Nilesh Maheshwari 53-64 4 Partitioning of Special Circuits. Bichitra Kalita 65-77 5 Modern Practices For Effective Software Development Process In Project Management. S. Mohamed Saleem, R. Selvakumar and C. Suresh Kumar 78-109 6 A Framework for IC-Technology enabled Supply Chains. Dr. V. Krishna Mohan and G Bhaskar N Rao 110-132 7 The Problem Of Outliers In Clustering. Prof. Thatimakula Sudha and Swapna Sree Reddy.Obili

Objective: The goal of this research is to build up a determined model of creation that unequivocally sees the arising tasks and scenarios of logistics in getting over new hoarding frameworks and authoritative designs and legitimate plans that have made due to new serious market pressure and competitiveness with a framework of a new theory ‘logistics strategic communication theory’. Methodology: The research method used for this research paper is contextual analysis. Findings: Logistics executives is a practice for organizations since it promotes competition and achieves improvements in the interest of the organizations. Logistics get combined into the general administration of the organization, bringing about a progression of data between various cycles and entertainers associated with the inventory network. Implications: The presentation of ICT and the exceptional mechanical upheaval have made another serious climate, in light of the globalization of the economy and solid rivalry....

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Shanlax publication, 2018

Computer and Information Science, 2010

… Journal of Physical Distribution & Logistics …, 2003

Production Planning & Control, 2004

International Journal of Physical Distribution & Logistics Management, 2002

Purakala with ISSN 0971-2143 , 2020

e-Journal of Social & Behavioural Research in Business, 2020

International Journal of Engineering, Science and Technology, 2013

SCM 4 ECR, 2009

Journal of Transport and Supply Chain Management

International Journal of Econometrics and Financial Management, 2014

IAEME PUBLICATION, 2020

Related topics

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Supply chains: Still vulnerable

Supply chain disruptions keep on coming. From missile attacks on commercial shipping in the Red Sea to automotive production delays following floods in Europe, global supply chains continue to experience instability. Meanwhile, trade tensions are choking the movement of semiconductor products, manufacturing equipment, and critical materials.

About the research

The fifth annual McKinsey Global Supply Chain Leader Survey was conducted among senior supply executives from a range of industries and geographies (exhibit). A total of 88 leaders completed the in-depth survey, which asked them about the status and evolution of their supply networks, planning, digitization, and risk management processes. Responses were collected between April 26 and June 10, 2024.

The latest McKinsey Global Supply Chain Leader Survey suggests that problems like these remain the norm, not the exception, with nine in ten respondents saying they have encountered supply chain challenges in 2024 (see sidebar, “About the research”). More worryingly, there are signs that, when it comes to supply chain resilience, companies are taking their foot off the gas. The survey results identify considerable gaps in the ability of organizations to identify and mitigate supply chain risks, with few new initiatives aimed at addressing those weaknesses.

The biggest gap could be the one at the top of the organization. Few surveyed supply chain executives believe that their boards have an in-depth understanding of supply chain risk. Only a quarter have formal processes in place to discuss supply chain issues at board level. All this could leave companies dangerously exposed to future disruptions.

A brief history of turbulent times

Since 2020, McKinsey has conducted annual surveys of supply chain leaders to ask about the performance of their supply chains, the impact of volatility and disruption on their supply chains, and their efforts to manage those challenges. The surveys occurred during a period of unprecedented supply chain turbulence that included the COVID-19 pandemic and its aftermath. This environment pushed supply chains to the top of the agenda, as companies took action to keep their businesses running in difficult conditions.

Those actions were initially rapid, tactical changes, with a focus on larger inventories and buffer stocks. But companies also took more strategic actions, accelerating projects to improve supply chain visibility, revamping their planning capabilities, and pursuing regionalization and dual-sourcing strategies to improve structural resilience.

Progress made

Our latest research shows that companies are now reaping the benefits of the strategic resilience projects they have implemented over the past three years. Supply chain footprints are evolving, with 73 percent of survey respondents reporting progress on dual-sourcing strategies. Additionally, 60 percent of respondents are acting to regionalize their supply chains.

Survey respondents also report good progress in their efforts to improve supply chain intelligence, planning, and risk management. The share of respondents with comprehensive visibility of their tier-one suppliers reached 60 percent, making this the second year in a row that this measure has increased by ten percentage points. More than three-quarters of companies believe they have sufficient internal capabilities to manage supply chain risk, along with effective decision-making structures.

Two-thirds of survey respondents say that they are making progress in the implementation of advanced-planning and -scheduling (APS) systems. These systems make up a key component of modern supply chain digitization. They enable companies to plan more accurately, respond to disruptions more rapidly, and improve their resilience by evaluating multiple supply chain scenarios.

Furthermore, companies are beginning to unwind the short-term measures that they put in place during and immediately after the COVID-19 pandemic. The number of survey respondents relying on bigger inventory buffers to manage disruptions has fallen sharply to 34 percent, from 59 percent. Some of that drop was forced upon them, however: 6 percent of respondents report that they wanted to increase safety stocks but were prevented from doing so by cash or capacity constraints.

Perspectives on future inventory strategy are evenly split among survey respondents (Exhibit 1). A share of 47 percent say that they plan to keep their overall inventories at current levels, with some planning changes in assortment or location across their networks. Meanwhile, 46 percent of respondents expect to reduce or eliminate risk buffers, with inventories falling back to or below prepandemic levels. Only 7 percent are planning further increases in network inventory.

Progress slowing

There are also plenty of signs that the revolution in supply chain resilience is losing momentum. The percentage of respondents pursuing dual-sourcing, regionalization, or nearshoring strategies has remained flat over the past two years, for example (Exhibit 2). Overall investment in supply chain digitization is leveling off after rapid growth between 2020 and 2023.

While two-thirds of surveyed companies are investing in APS systems (up 14 percentage points from the previous year’s numbers), only 10 percent have completed their deployments. And companies are unclear about the value that these systems deliver. One-third of respondents admit that they don’t have quantified business cases for APS systems, and 15 percent say that their implementations haven’t met business objectives (Exhibit 3).

Considerable gaps remaining

This slowdown in resilience-boosting activity for supply chains would be understandable if organizations had completed the work that they set out to do. But survey respondents are all too aware of limitations in their supply-chain-management systems. Companies continue to improve their understanding of direct suppliers, for example. The share of respondents who say that they have good visibility into deeper levels of the supply chain fell by seven percentage points, the second consecutive annual decline in this measure (Exhibit 4).

This should be a concern because major disruptions often start deep in the supply chain. And once companies experience a supply chain disruption, it takes them an average of two weeks to plan and execute a response—much longer than the typical weekly cycle for sales and operations execution.

Meanwhile, pressure for better transparency in the deep-tier supply chain is rising. New supply chain laws increasingly require companies to ensure that all inputs are produced in compliance with environmental and human rights standards. The European Union’s Corporate Sustainability Due Diligence Directive is already in force for some companies, for example. Only 9 percent of survey respondents say that their supply chains are currently compliant with the new rules, with 30 percent admitting that they are behind or significantly behind in their compliance efforts.

A shortage of talent, particularly digital talent, continues to hamper supply chain transformation efforts. Of those surveyed, 90 percent say that their companies lack sufficient talent to meet their digitization goals. That number hasn’t changed in any meaningful way since the first survey in 2020.

Survey respondents also remain concerned that their senior management teams have a limited knowledge of supply chain issues. The share reporting that their boards have a deep understanding of supply chain risks increased this year but remains low at 30 percent. Perhaps more concerning is a steep drop in the frequency that supply chain risks are discussed at a senior-management level. In the 2023 survey, almost one-half of respondents said that their organizations had a regular reporting cadence for supply chain risk. This year, that share dropped to one-quarter, with most companies reverting to ad hoc reporting in response to disruptions or the emergence of major new risks.

The way forward

To stay ahead of future supply chain challenges, companies must continue their ongoing efforts to build resilience and take new actions to address blind spots in their systems, processes, and capabilities. The data from our survey provide some insights into how this can be achieved.

Don’t let imperfect data be the enemy of good digitization

Data issues make up a major bottleneck for many ongoing digitization projects. While there is a correlation between data quality and the value achieved from digital efforts with supply chains, no survey respondents with deployed APS systems think that their data are perfect, yet many are satisfied with the performance of their new systems. This suggests that companies might benefit from approaching data quality with the 80/20 rule by pressing on with the implementation of digital tools once most data are available, with processes in place to fix the gaps later.

Take on the talent-building challenge

The past three years have seen a dramatic shift in how companies approach digital-talent acquisition (Exhibit 5). After slightly favoring a homegrown approach in 2021, most respondents had turned to the market to fill talent gaps by 2023. This year, the pendulum has been swinging back again. Faced with an acute shortage of digital talent across all industries, company leaders are now revamping their internal training and talent development capabilities. In the long run, this may be the most effective way to secure a sustainable supply of skills.

Accelerate the adoption of AI

The rapid development of advanced digital tools is opening new opportunities in supply chain planning, operations, and risk management (Exhibit 6). These tools are already shaping organizations’ digitization plans, as evidenced by a substantial increase in interest in demand-planning tools. In the coming years, we expect these technologies to provide additional functionality in other areas.

A major opportunity is in supply planning: AI systems can automate the analysis of multiple structured and unstructured data sources from multiple supplier tiers, logistics providers, shop floor data systems, and in-house demand-forecasting systems. Another is in early-warning systems for potential supply chain risks that evaluate data from sources as diverse as supplier financial information, long-range weather forecasts, and social media traffic.

Close the boardroom gap

Supply chain leaders failed to grab a seat at the top table when supply disruption was at the forefront of senior-management teams’ agenda. Now they must find ways to educate and inform senior management about supply chain issues and challenges. Best practice here is still rare, but some survey respondents are taking proactive steps, including giving regular board updates on major risks, risk trends, and potentially disruptive events; integrating risk analysis more explicitly into sale- and operation-planning processes; and publishing regular risk reports and quantitative risk indicators.

While companies have made strides in strengthening their supply chains, the latest McKinsey Global Supply Chain Leader Survey shows that substantial vulnerabilities remain. A slowdown in resilience-building efforts, gaps in supply chain visibility, compliance challenges, and talent shortages leave many organizations exposed to future disruptions. To safeguard against these risks, businesses must prioritize ongoing digitization, talent development, and proactive risk management while ensuring that supply chain issues receive attention at the highest levels of leadership.

Is your organization paying enough attention to supply chain resilience? As a simple gauge, consider how many of these questions you can confidently answer with “yes”:

- Do you have a plan to build or acquire the digital talent your supply chain needs?

- Do you understand the risk status of your tier-two and tier-three suppliers?

- Do you have an effective early-warning system for internal and external supply chain risks?

- Does your supply planning use AI to evaluate risk scenarios quantitatively?

- Is your average time to recovery from supply chain disruptions less than one week?

- Does your board thoroughly understand supply chain risks?

- Is your board willing to budget for the mitigation of supply chain risks?

Knut Alicke is a partner in McKinsey’s Stuttgart office, Tacy Foster is a partner in the Carolinas office, and Vera Trautwein is a senior expert in the Zurich office.

Explore a career with us

Related articles.

Taking the pulse of shifting supply chains

Tech and regionalization bolster supply chains, but complacency looms

- Café con Logística

- Episode Highlights

- Global Trade

- Industry Trends

- Logistics Leaders for T1D Cure Team

- Regulations

- Transportation Management

- Descartes Channel

- E2open Channel

- Uber Freight Channel

- Infor Nexus Channel

- Transporeon Channel

- Manhattan Associates Channel

- JBF Consulting Channel

- Loadsmart Channel

- Parcel Perform Channel

Revisiting Data Quality in Supply Chain Management

- By Adrian Gonzalez

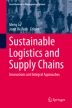

On a more positive note, more than half the respondents (54%) said that the quality of their supply chain data has been either “Improving” (50%) or “Greatly Improving” (4%) in the past 3 years; only 8% said that it was “Worsening.”

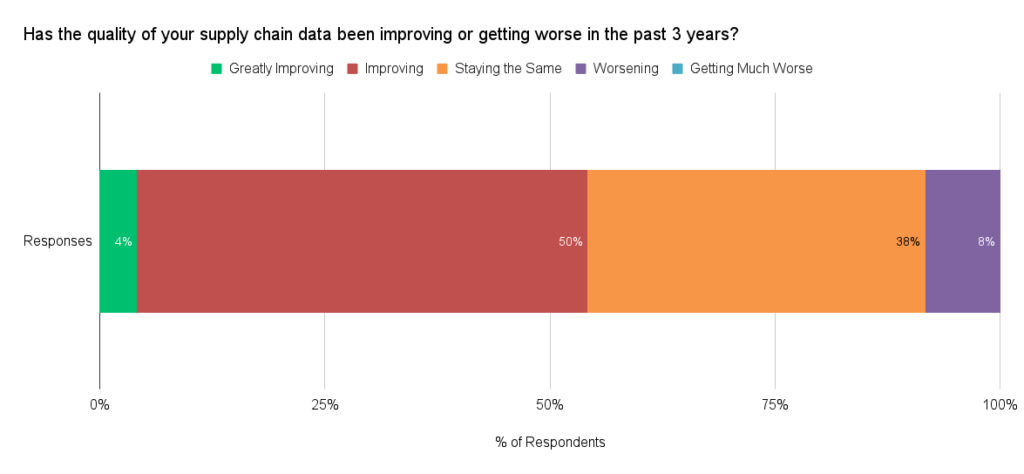

Who is primarily responsible/accountable for supply chain data quality management at your company? Part of the problem, as the chart below shows, is that nobody is formally accountable at many companies.

“The root cause of poor data quality is that it is segmented and siloed, giving an incomplete view of what is going on,” said one Indago supply chain executive.

Here are some other comments from our Indago executives:

“Our company has created a centralized Data Governance team to document accountability across all data inputs. Data is not just a supply chain issue, it’s an end-to-end business one.” “Data quality issues are as much (or even more) an internal problem than an external one. Data management is not currently an area of focus for us, but that is where the primary actions for improvement reside.” “Data and the management of data have become impossibly complex, especially in large global organizations. No single group has full responsibility or even understanding of the data sources, job runs, etc. End business users are even more in the dark and have no way to understand or troubleshoot when inaccuracies are found. When the data is there and available, it’s a wonderful thing and we can harness it to drive powerful insights, but when it’s not, we’re back in the dark ages.” “I am with a new company now, and the issue here (and maybe with others) is the lack of ownership. At this point in time, IT owns data quality management which does not work; buyers/supply chain areas [need to own it]. As we all know, it is tough when the people dealing with the data coming in do not understand the long-term pain of inaccurate or missing data.”

For additional insights from the research, including which component of data quality (Accuracy, Timeliness, or Completeness) requires the most improvement from trading partners, Indago members can download the report from our website.

What are the root causes of poor data quality? What are the main challenges to improving it? What actions, if any, are you taking to improve data quality?

Post a comment and share your perspective!

- data quality management , Indago , supply chain

Subscribe to Our YouTube Channel

- Above the Fold (20)

- April Fools (3)

- Business Advice (17)

- Business Intelligence (35)

- Case Study (36)

- Cloud/SaaS (71)

- Editor's Pick (85)

- Educator Perspective (3)

- Episode Highlights (341)

- Executive Perspective (10)

- Global Trade (153)

- Global Trade Management (78)

- Guest Commentary (444)

- Guest Commentary – 3Gtms (14)

- Guest Commentary – Amber Road (11)

- Guest Commentary – AXIT (4)

- Guest Commentary – BluJay Solutions (3)

- Guest Commentary – Blume Global (10)

- Guest Commentary – Breakthrough (5)

- Guest Commentary – CH Robinson (31)

- Guest Commentary – ClearMetal (3)

- Guest Commentary – CLX Logistics (8)

- Guest Commentary – Command Alkon (6)

- Guest Commentary – Descartes (32)

- Guest Commentary – E2open (49)

- Guest Commentary – Elemica (25)

- Guest Commentary – Emerge (4)

- Guest Commentary – enVista (12)

- Guest Commentary – GEODIS (9)

- Guest Commentary – Grand Junction (4)

- Guest Commentary – GT Nexus (8)

- Guest Commentary – Infor (3)

- Guest Commentary – JBF Consulting (8)

- Guest Commentary – JDA Software (4)

- Guest Commentary – Kenco Group (14)

- Guest Commentary – Kewill (10)

- Guest Commentary – Kuebix (10)

- Guest Commentary – LeanLogistics (13)

- Guest Commentary – LEGACY SCS (2)

- Guest Commentary – LLamasoft (8)

- Guest Commentary – Loadsmart (1)

- Guest Commentary – Manhattan Associates (7)

- Guest Commentary – MercuryGate (26)

- Guest Commentary – MP Objects (11)

- Guest Commentary – Parcel Perform (2)

- Guest Commentary – PINC Solutions (13)

- Guest Commentary – Quintiq (5)

- Guest Commentary – ReverseLogix (1)

- Guest Commentary – RouteSmart (8)

- Guest Commentary – Ryder (4)

- Guest Commentary – SAP (4)

- Guest Commentary – Tive (1)

- Guest Commentary – Transplace (48)

- Guest Commentary – Transportation Insight (7)

- Guest Commentary – UltraShipTMS (9)

- Guest Commentary- Command Alkon (1)

- Indago (110)

- Industry Trends (545)

- IT Trends (9)

- Just for Fun (33)

- Latin America (2)

- Leadership Development (58)

- Life Stories (28)

- Mergers/Acquisitions (110)

- Outsourcing (36)

- Packaging (6)

- Past Episode (391)

- Past Episode – 3Gtms (13)

- Past Episode – Amber Road (8)

- Past Episode – Axit (4)

- Past Episode – BluJay Solutions (21)

- Past Episode – Blume Global (8)

- Past Episode – Breakthrough (4)

- Past Episode – CH Robinson (29)

- Past Episode – ClearMetal (4)

- Past Episode – CLX Logistics (4)

- Past Episode – Command Alkon (5)

- Past Episode – Descartes (24)

- Past Episode – E2open (34)

- Past Episode – Elemica (18)

- Past Episode – Emerge (6)

- Past Episode – enVista (12)

- Past Episode – GEODIS (7)

- Past Episode – GT Nexus (8)

- Past Episode – Infor (1)

- Past Episode – JDA Software (6)

- Past Episode – Kenco Logistics (9)

- Past Episode – Kewill (8)

- Past Episode – LeanLogistics (12)

- Past Episode – LEGACY SCS (2)

- Past Episode – LLamasoft (4)

- Past Episode – MacroPoint (1)

- Past Episode – Manhattan Associates (5)

- Past Episode – MercuryGate (20)

- Past Episode – MP Objects (6)

- Past Episode – Nulogy (1)

- Past Episode – PINC Solutions (2)

- Past Episode – project44 (3)

- Past Episode – Quintiq (3)

- Past Episode – RouteSmart (4)

- Past Episode – Ryder (5)

- Past Episode – SAP (1)

- Past Episode – Transplace (29)

- Past Episode – Transporeon (1)

- Past Episode – Transportation Insight (3)

- Past Episode – TranzAct (3)

- Past Episode – Trucker Tools (19)

- Past Episode – UltraShipTMS (8)

- Quick Poll (1)

- Regulations (71)

- Research in Focus (12)

- Retail (80)

- Retail Trends (77)

- Robots (89)

- Social Media (32)

- Supply Chain & Logistics Books (6)

- Supply Chain & Logistics Trends (326)

- Supply Chain and Logistics Predictions (6)

- Supply Chain Risk Management (115)

- Supply Chain Technology Trends (368)

- Sustainability (40)

- Technology (391)

- Thanksgiving (1)

- This Week in News (541)

- Transportation Management (800)

- Transportation Management Systems (401)

- Uncategorized (7)

- Upcoming Episodes (1)

- Warehouse Management (41)

- Young Professionals (6)

Subscribe to Our Podcast

Trending posts.

- Above the Fold: Supply Chain Logistics News (October 11, 2024)

- Supply Chain and Logistics Conferences to Attend in 2024

- How Much Would You Pay for Drone Delivery?

- Walmart Launches Multichannel Logistics and Cross-Border Fulfillment Services

- How Stressful Is Working in Supply Chain Management?

- Labor Shortages: What Are the Challenges for Supply Chain and Logistics?

©2012-2024 Adelante SCM. All Rights Reserved. The content of Talking Logistics may not be reproduced or distributed without prior written approval. Please read our Terms of Use for more details.

COMMENTS

Abstract. In the current landscape of global commerce, logistics and supply chain management stand at the forefront of both opportunity and challenge, significantly influenced by the relentless ...

Supply chain management (SCM) remains an important topic among logistics managers, researchers and educators. This paper opens by describing four unique perspectives on the relationship between ...

the following three perspectives: (1) development of methods and techniques to study SCM. and its components/processes; (2) developing solutions or answers to specific supply chain-. related ...

The purpose is threefold: to identify research topics in logistics and supply chain management where one or more theories have been examined; provide commentary on the theories that have been applied to the various logistics and SCM research topics; and to provide reference material and direction for future research.

Journal of Supply Chain Management (JSCM) is an international empirical journal known for its high-quality, high-impact research in the discipline of supply chain management. We welcome interdisciplinary research that employs qualitative or quantitative methods to develop, advance, or test theories, present novel interpretations, or challenge existing assumptions about SCM phenomena.

This article continues the longest-standing evaluation of publication productivity in the academic field of supply chain with the combined series spanning 55 years. In this edition, we update the schools and individual scholars producing the most supply chain publications from 2020 to 2022.

Download PDF. Annals of Operations ... This special issue covers a wide range of topics related to logistics, supply chain management and related areas where advanced operational research (OR) and management science (MS) methods, theories, and methods are used and further developed. The scope of the special issue study includes the following ...

nals within logistics and supply chain management (Gibson et al., 2003). 4.2 Assessing Review Time Frame The year 1997 was chosen as the starting point for selecting papers for reviews since the first coherent frameworks of supply chain management were published in this year (Bechtel & Jayaram, 1997, Cooper et al., 1997). Bechtel & Jayaram

The purpose is threefold: to identify research topics in logistics and supply chain management where one or more theories have been examined; provide commentary on the theories that have been applied to the various logistics and SCM research topics; and to provide reference material and direction for future research.,This structured literature ...

Chapter 1Introduction to Logistics and Supply Chain ManagementAbstract In this chapter we provide a brief introduc. ion into the concepts of logistics and supply chain management. Considering different production factors, functions and processes in a company and across companies both terms are spec-ifie.

Abstract. The study is a systematic literature review of current state of research on the dyadic relationship of supply chain management practices with supply chain performance measures published in empirical research articles in literature. Forty-three empirical research papers published in high quality Scopus and WoS indexed Journals between ...

PDF | On Feb 1, 2012, Andrzej Szymonik published Logistics and Supply Chain Management | Find, read and cite all the research you need on ResearchGate

Total logistics costs are the sum of inventory, transportation, and facility costs for a supply chain network. As the number of facilities is increased, total logistics costs first decrease and then increase as shown in Figure 4.3. Each firm should have at least the number of facilities that minimize total logistics costs.

Boeing Aircraft announced a write-down of $2.6 billion in October 1997 due to "raw material shortages, internal and supplier parts shortages and productivity inefficiencies . . ." [161]. "Second quarter sales at U.S. Surgical Corporation declined 25 percent, resulting in a loss of $22 million.

The cases were selected on the main criteria: (i) the focus of the project should be connected to logistics, supply chain management, or both, (ii) the cases should be based on an interactive research design and carried out utilizing the IR approach, and (iii) the cases must be based on critical sampling, providing complementary perspectives ...

tage and improved supply chain performance. This qualitative research fills a gap in previous research by exploring the phenomenon of Interfirm Demand Integra-tion in a true supply chain context, garnering perceptions from multiple supply chain partners. Results are expected to contribute to managerial, theoretical, and methodological knowledge.

Part 1 establishes the strategic importance of logistics to achieving business success by creating value throughout domestic and global supply chains. The initial chapter scopes the current business attention to supply chain management. The supply chain provides the framework within which logistical strategies are developed and executed.

This chapter provides an overview of the trends and challenges in the area of logistics and supply chain management and addresses the needs for research and innovations. In addition, it describes the structure and the main themes of the other chapters of this book. Download chapter PDF.

Abstract This paper is aimed at introducing the concept of reverse logistics (RL) and its implications for supply chain management (SCM). RL is a research area focused on the management of the recovery of products once they are no longer desired (end-of-use products, EoU) or can no longer be used (end-of-life products) by the consumers, in ...

BookPDF Available. Logistics and Supply Chain Management: Fundamentals and Strategies. January 2023. ISBN: 979-8375061962. Authors: Turkay Yildiz. Izmir Institute of Technology. Citations (2 ...

Logistics and supply chain management are the key means for promoting economic development. Logistics involves not only the efficient flow of materials, but also the timely transmission of information and the optimal allocation of resources, which plays an important supporting role in the operation of global supply chains and ensures the smooth flow of goods from production to consumers.

E-logistics helps in managing the new challenges in the supply chain field. The main components of the e-logistics are multi-channel operations, cross-border tasks, warehouse plan and inventory, planning, estimating and performance management. This study targets to understand the main benefits and the new tasks between logistics and e-logistics.

The fifth annual McKinsey Global Supply Chain Leader Survey was conducted among senior supply executives from a range of industries and geographies (exhibit). A total of 88 leaders completed the in-depth survey, which asked them about the status and evolution of their supply networks, planning, digitization, and risk management processes.

This conceptual paper outlines the importance of integration in supply chain management (SCM) by linking the functions of logistics as it applies in strategic business process. Often, business ...

Source: June 2024 Indago survey of 24 qualified and verified supply chain and logistics executives from manufacturing, retail, and distribution companies. On a more positive note, more than half the respondents (54%) said that the quality of their supply chain data has been either "Improving" (50%) or "Greatly Improving" (4%) in the ...

Top Mattel supply chain executive offers up five lessons for managing supply chain complexity and change ... ATRI's annual Operational Costs of Trucking research documented industry cost increases of over 22 percent over the past two years—the highest recorded costs in the research's 16-year history. ... Logistics Management has curated ...

Abstract. Purpose This paper aims to review logistics and supply chain management topics where theories have been applied to better understand the supply chain management (SCM) discipline identity ...